Why Choose Automatic Rebar Tier? 3 Core Advantages Transforming Traditional Construction

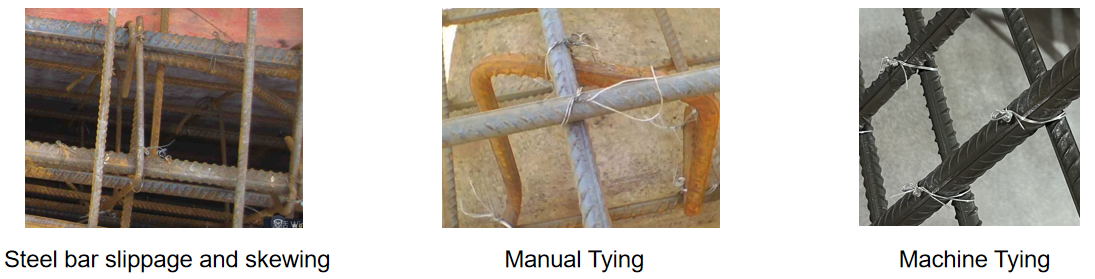

Ⅰ. Ensure Quality and Reduce Safety Risks

Manual tying is highly susceptible to worker experience and physical fatigue, often resulting in loose or broken ties. This can lead to deformation or displacement of the rebar framework during concrete pouring, directly compromising structural integrity. The intelligent tying machine utilizes digital tension control to produce consistently uniform and tight ties, effectively preventing loosening or wire breakage during construction. It ensures rebar spacing meets specifications, guaranteeing project quality from the source.

Ⅱ. Significantly Reduce Costs and Boost Efficiency

The intelligent steel bar tying machine can complete a single tie in as fast as 0.45 seconds. A single machine's efficiency is equivalent to that of 3-5 workers, drastically reducing labor requirements. Furthermore, the machine employs precise wire feeding and retrieval mechanisms, leading to substantial savings in binding wire compared to manual methods. Overall, it can reduce total labor and material costs by up to 75% and shorten project timelines.

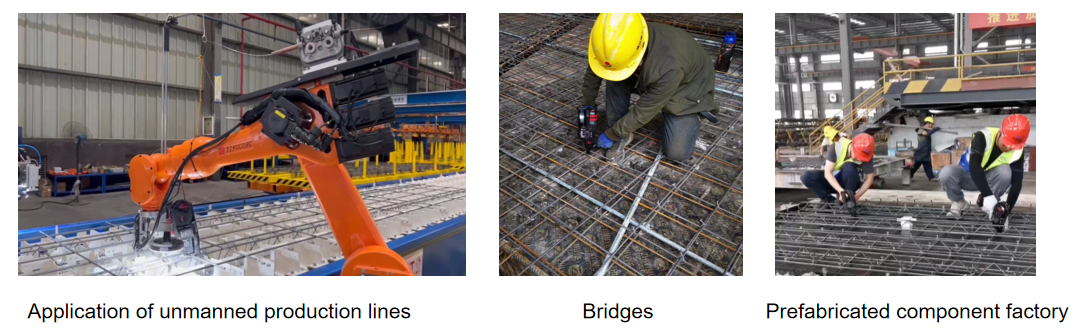

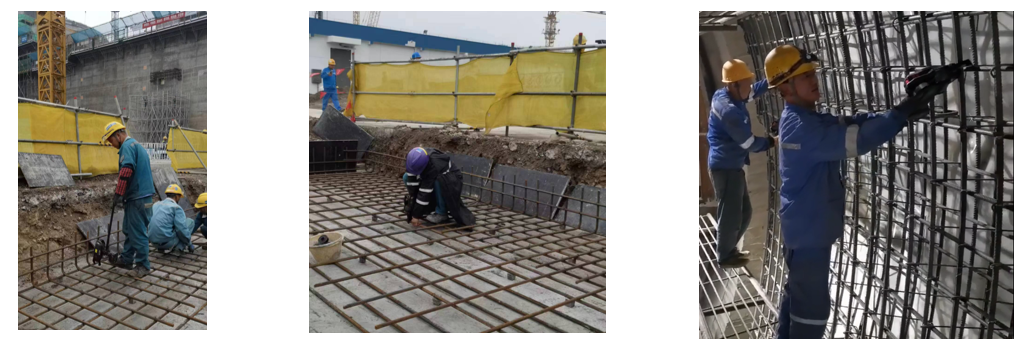

Ⅲ. Adaptable to Diverse Scenarios, Easy and Effortless Operation

The equipment features an ergonomic design, weighing only 2.5-2.9 kg, and can be operated single-handedly, reducing work-related injuries to the hands, arms, and back. With an IP54 protection rating, it performs reliably in complex construction environments—whether in bridge construction, precast component plants, or standard building projects. Certain models can also be integrated with industrial robots to enable unmanned production of precast concrete components.